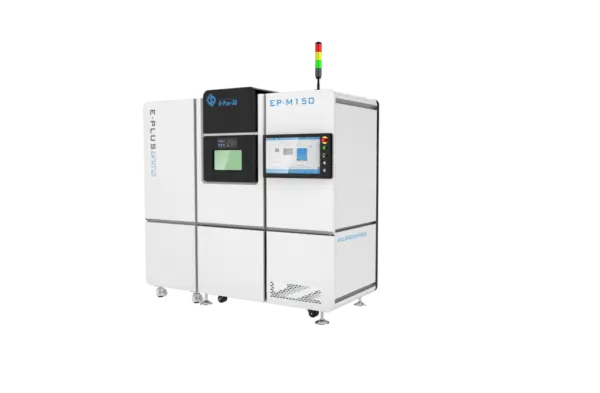

EP-M150Pro Metal

If you take the standard EP-M150 Metal and add a more powerful laser, increase the speed, make the build volume larger, and add more accuracy to the machine, you’re left with an EP-M150Pro. That’s exactly what the team at EP did to put together this high-caliber EP-M150Pro.

The EP-M150Pro offers the same durability and reliability that you can find in other EP products, but it has power and accuracy that you might not expect. While the build volume is still on the smaller side, the added height will allow you to make a wider range of products.

Your engineering team might buy the EP-M150Pro if you’re looking to make detailed, smaller parts out of pure metal. With this metal 3D printer, your final parts can be close to 100% metal by volume.

In the big scheme of things, the EP-M150Pro is one of the more affordable 3D printers, based on all the functionality you get from this machine.